Few products come in glass jars these days, and plastic plastic packaging is everywhere. The plastic bottle war has been going on for sometime now, but it’s not just water bottles that are the problem, from peanut butter jars to 2 litre coke bottles, these bottles are all made the same way. Regardless of the form of plastic, it has negative consequences for the environment. Especially when it is not recycled. Plastic wasn’t always used the way it is today. The earliest form of plastic dates back as far as 3500 years ago. The ancient Mesoamericans first processed natural rubber into balls, bands and figurines. They would harvest latex from the Panama Rubber Tree plant and process it using liquid from the ‘Morning Glory Vine’. Modern day plastic made its first appearance during World War II when it was used for military purposes because it was more durable than glass and had a greater range of possible products that could be made from it. Items like tents, raincoats, and windshields for military vehicles were made. Once the war ended manufacturers needed to find new ways to create plastic products that people would want. This is where our plastic addiction began. Since the 1950’s, the plastic industry has been booming. From the r

enowned Tupperware parties to nylon stockings the world became obsessed with plastic. Single use plastics and packaging especially. It changed the way grocery stores sold products, even to this very day. The items are everywhere but where do plastics actually come from? How is it made? Today most plastics are made of fossil fuels.

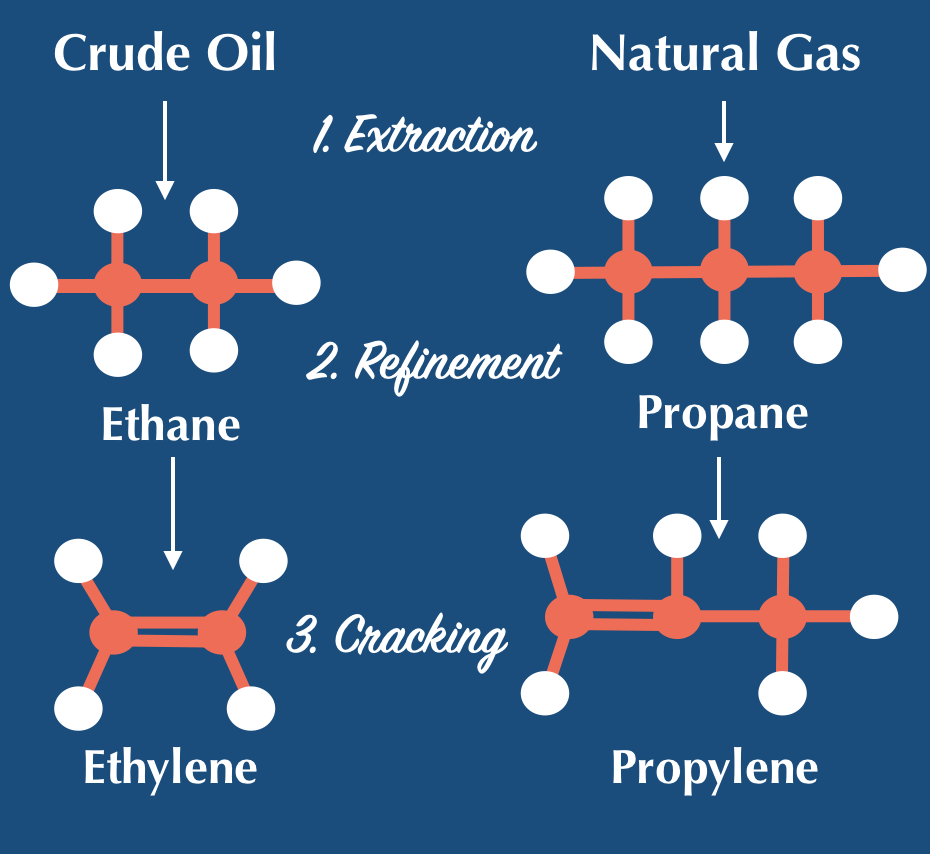

Step 1. Extraction

Crude oil and natural gas are extracted from the ground

Step 2. Refinement

Crude oil and natural gas go to refinement to be turned into multiple different products. Including ethane from crude oil and propane from natural gas. These products are the building blocks of plastics.

Step 3. Cracking

These molecules of propane and ethane are broken down into smaller molecules called propylene and ethylene

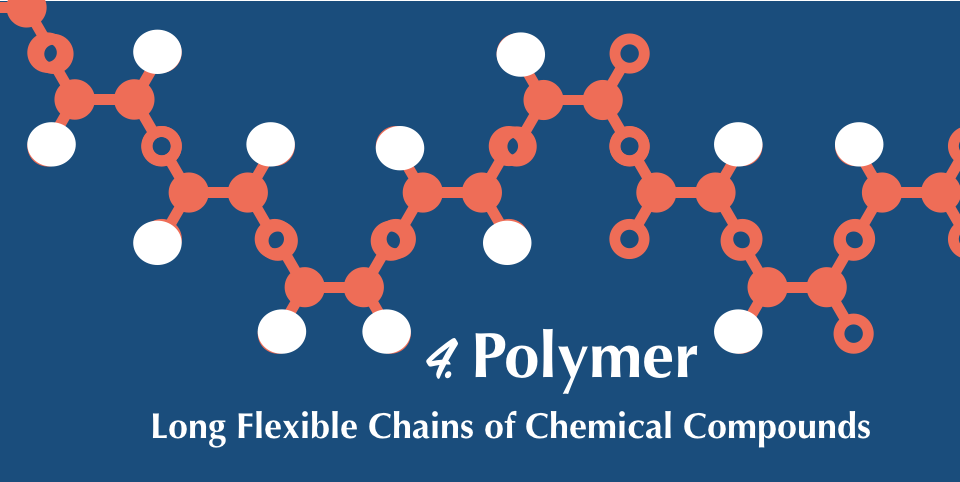

Step 4. Polymerization

A catalyst is added to make the individual molecules stick together making a polymer. A polymer is a long flexible chain of chemical compounds. These polymers are what allow plastic to be excellent for making products because they are easily

moveable and moldable when heated. These polymers are called resins. This is where the resin ID comes in, the little mobius loop with the number in the middle indicates the type of polymer the plastic is composed of.

Step 5. Creating Usable Material

These resins are then melted, cooled down and chopped up into little pellets called nurdles.

Step 6. Sending nurdles to the manufacturer

From here the nurdles are sent to different bottle manufacturers. These nurdles are first melted and mixed with usually 10% recycled flakes of the same plastic. This is because recycled plastic has a lower quality and loses some

of its chemical properties. If too much recycled plastic is mixed in, the product would not be of high enough quality.

Step 7. Creating Plastic Preforms

The melted plastic goes into an injection machine

that heats it to about 600 fahrenheit. This plastic is then shot into molds to make preforms.

Each plastic injection moulding machine is used to make a different preform for a different shape for a different bottle or jar.

Step 8. Creating Plastic Bottles

The next step is a reheat stretch blow moulding machine. The preforms are heated just enough to make the plastic malleable. A rod is inserted to stretch the preform lengthwise and then high pressure air is blown into the preform to expand it into the desired shape.

Step 9. Quality Control

Each new plastic bottle goes through a series of quality control tests such as thickness tests and pressure checks to make sure that the quality of the product is up to standard.

Step 10. Bottles go for labeling and filling!

Bottles go to be labeled with their desired paper labels and then filled with the material they are made for. Whether it be peanut butter or water!

With all of the plastic products that surround us, they can be hard to avoid. We are currently going through what people are calling the “war on plastics”. There are places in Canada banning single use products like straws, and some Universities have ban bottled water. The main reason for this being environmental consciousness.

Previously it has been mentioned in other blog posts and social media posts, that plastic never really leaves the environment once it has been produced. It only breaks down into smaller and smaller pieces, called microplastics and it is forever in the ground and waterways. But what are the negative consequences of plastics on our health while we are using plastics, even before we dispose of them? In and out of the news BPA has been mentioned numerous times. BPA stands for bisphenol A. BPA is an industrial chemical that has been used to make certain plastics and resins since the 1960s.

BPA is found in polycarbonate plastics and epoxy resins. Polycarbonate plastics are often used in containers that store food and beverages, such as water bottles. According to The Mayo Clinic, exposure to BPA is a concern because of possible health effects of BPA on the brain, behavior and prostate gland of fetuses, infants and children. Although according to the Food and Drug Administration BPA is safe in very small quantities it’s still something to be aware of when buying plastic products. There is currently no law saying that products cannot be made with BPA nor do they have to disclose that if there is BPA in a plastic product. So when possible avoid buying food products in plastic not only does it benefit your health but it can also benefit the planet’s health.